Connect With Our Team

In the world of minerals, one technical term you often run into is 'mesh size.' It sounds complicated and can be, but mesh size is hugely important in how minerals are processed, separated and consumed in industries such as construction, ceramics, glass, cosmetics and pharmaceuticals. This guide is for the beginner who wants to understand what mesh size means and why it matters. In this article, we walk you through the concept, why it matters and how it plays an important role in quality mineral production.

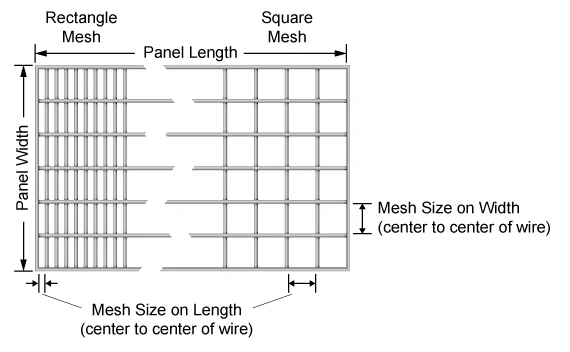

The mesh size is the number of openings in one linear inch of any sieve used to separate mineral particles by size. It is a standard method for describing the size distribution of mineral powder and aggregates.

Mesh number determines the size of the particle; for instance 200 mesh means a higher mesh number and passes only very fine particles.

Lower mesh numbers work, like 20 mesh; they only allow the larger particles through and the finer ones remain.

Choosing the right material for your application depends on being able to understand mesh size, whether you need coarser granule sizes to work as added filters or ultra-fine powders to be used in paint or polymer fillers.

You can look at how mesh size does its job of filtering mineral particles through a woven wire screen. The holes scattered on the screen have a special number of holes per inch, but can only pass particles smaller than the holes. This enables manufacturers to separate and grade minerals according to size. Additional information on mesh screen types and sizes can be found by reading below

For example, a 60 mesh screen refers to a screen that has 60 holes per linear inch, small enough to allow particles smaller than that size to pass.

Mesh size is sometimes given as a range e.g -60 +100 mesh particles that passed through a 60 mesh screen and were retained in a 100 mesh screen.

The sieving process that this sieve provides enables precise, consistent and controllable particle sizing, all features required for industrial applications.

Mineral powders are classified based on standardized mesh sizes that are closely related to particle diameters. Below is a quick reference table for commonly used mesh sizes:

Mesh Size Approx. Particle Size (Microns)

10 Mesh 2000 μm (2 mm)

40 Mesh 425 μm

60 Mesh 250 μm

100 Mesh 150 μm

200 Mesh 75 μm

325 Mesh 44 μm

This classification helps industries like ceramics, paint, rubber, plastic, and construction choose the most suitable grade for their application needs.

Selecting the right mesh size is critical for both performance and production. Here are some reasons why it holds importance:

Performance Optimization: Particle size affects how minerals react, blend or bond in formulations and is the single most important performance parameter. Surface area and reactivity are enhanced in paints, cosmetics and coatings at finer mesh sizes.

Consistent Quality Control: A uniform mesh size makes it easier to maintain consistent product quality associated with uniform product strength, texture and appearance (such as ceramic, tiles, sanitaryware and plastics).

Improved Processing Efficiency: Correctly sized particles result in lower processing times and less energy consumed, as well as decreased wastage during manufacturing.

Specific End-Use Requirements: Different industries have differing end-use requirements for particle size, for instance, coarse quartz sized for glass manufacture and fine kaolin clay sized for paper coating or for cosmetics.

Mesh size is the number of openings in a screen and micron size is the actual diameter of the mineral particle. These two terms are sometimes used side by side to see a complete picture of particle size.

1 micron = 0.001 millimeter

Higher micron value = larger particle

Higher mesh number = finer particle

For instance, a 325 mesh talc powder has an approximate particle size of 44 microns. Understanding both metrics helps manufacturers ensure precision and meet application-specific requirements.

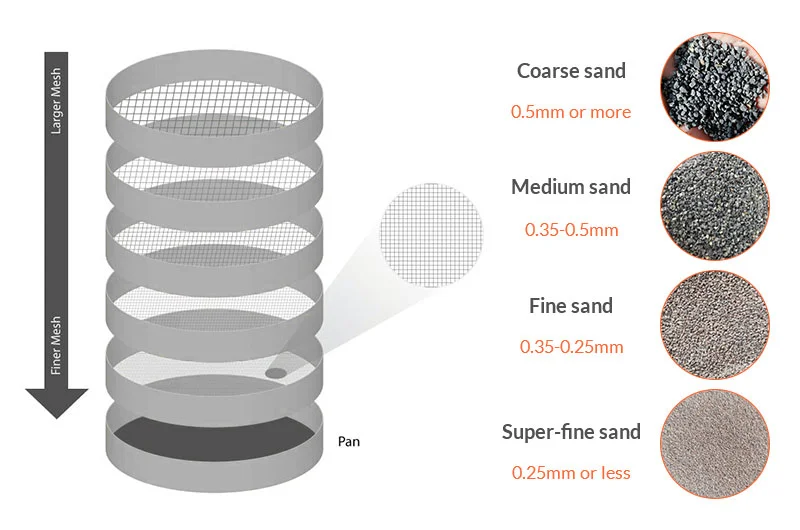

Sieve analysis is the standard method for determining mesh size by passing minerals through a stack of screens of progressively finer sizes; coarsest on top, finest at the bottom. The particles are captured in each sieve, representing the size range, and thereby they may measure the particle distribution quite accurately.

Minerals are weighed before and after sieving.

The amount retained on each sieve is recorded and expressed as a percentage.

The final result gives a mesh size range, such as 100–200 mesh, for the final product.

This method ensures accurate classification for minerals used in applications like electronics, glass, or construction fillers.

Mactus Mineral is your ideal partner if you’re looking for high-quality minerals and a wide range of meshes. Mactus Mineral has grown into the leading mineral mining and supplying company, manufacturing and supplying feldspar, ball clay, china clay, kaolin clay, quartz, talc, and mica in a wide range of mesh sizes to suit various industrial requirements.

A first in India, Mactus Mineral is proudly introducing 100% premium quality mesh feldspar powder produced in Wet wet-type processing plant having its integrated dryer a breakthrough in the Indian mineral industry. India’s biggest wet-type processing facility, with a production capacity of more than 550,000 TPA (tons per annum) mesh feldspar powder, is our business.

At Mactus Mineral, we have advanced processing technology, practice strict quality control, and are committed to sustainable practices by providing precision with particle sizing, continual chemical composition and purity of the minerals. Whether in ceramics, glass, paints, plastics or cosmetics, Mactus Mineral offers specific mineral solutions to drive up your product's performance and value.

A wide variety of industrial minerals – from coarse 20 mesh to ultra fine mesh 500 mesh – are explored and they are made to specifications of your industry by us.

To choose the appropriate mineral product for your industrial application it’s important to understand mesh size. Mesh size is key across all industry sectors, from improving product performance to guaranteeing consistency and decreasing costs of manufacturing.

As either a beginner or a manufacturer tinkering around with your material specifications, mesh size is an important concept to continue to keep in the back of your mind.

Dependable and precision-graded minerals are what you get at Mactus Mineral, where quality and consistency meet.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |