Connect With Our Team

Feldspar is one of the most common minerals on the earth and it comprises a major constituent of igneous rocks, metamorphic rocks as well as sedimentary rocks. Its special chemical composition (mainly aluminosilicates of potassium, sodium, and calcium) makes it invaluable to a vast number of industries. The choice of the appropriate grades of feldspar lumps is important in obtaining the intended performance in glass, ceramics, fillers, etc.

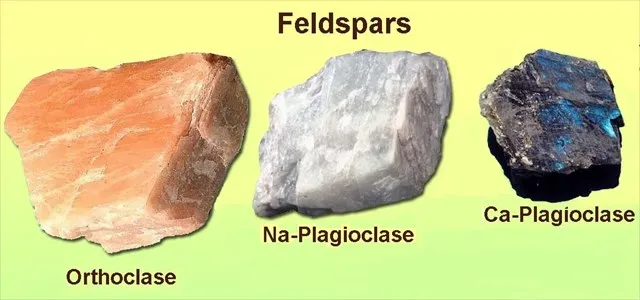

Feldspar is commercially classified based on its dominant alkali content:

Soda Feldspar (Sodium Feldspar): High in Naâ‚‚O, low in Kâ‚‚O; prized for glassmaking due to its fluxing properties and low iron content.

Potash Feldspar (Potassium Feldspar): High in Kâ‚‚O, low in Naâ‚‚O; preferred in ceramics for its ability to enhance vitrification and strength.

Mixed Feldspars: Contain significant amounts of both sodium and potassium, offering a balance of properties for blended industrial applications.

The other grades, such as commercial grades, are specified by its mineralogical composition (albite, microcline, anorthite), chemical analysis (alkali and alumina levels and iron impurities), and physical attributes (whiteness, particle size).

After mining, feldspar lumps undergo several processing steps:

Drying: Removes moisture for easier handling and storage.

Milling: Achieves the required particle size for specific applications.

Blending: Customizes the alkali and alumina content by mixing different grades.

Grade selection depends on the intended industrial use. For instance, low-iron, high-whiteness feldspar is essential for glass and high-end ceramics, while fine-milled grades are used as fillers in paints and plastics.

This high-purity feldspar contains superior levels of potassium or sodium with minimal impurities. It is used where whiteness, strength, and smoothness are essential, such as:

Porcelain manufacturing

Transparent glass

Sanitaryware

High-end ceramics

More economical and suitable for general-purpose applications where ultra-whiteness isn’t required. Commonly used in:

Bricks

Low-end ceramic tiles

Cement products

Characterized by controlled granule size and moderate fluxing content, it promotes vitrification and body strength in:

Wall and floor tiles

Sanitaryware

Tableware

Glass-grade feldspar has low iron content and balanced alumina and alkali levels. It improves the clarity and thermal durability of:

Flat glass

Container glass

Automotive windshields

Feldspar lumps processed for micronized applications serve as fillers in:

Paints

Coatings

Plastics

Rubber compounds

Feldspar is a fluxing agent, which lowers the melting temperature of quartz and assists the mixture to transform into a glassy phase. This plays a vital role in tile production, sanitaryware and dinnerware.

Micronized feldspar improves the consistency of the paint, being an anti-blocking agent and facilitating weather resistance.

Feldspar enhances strength of products, minimizes product shrinkage and cross sectional impact resistance in molding of plastic products.

The coating of the welding rods contains feldspar to enhance the flow properties and stability of the arc.

The feldspar in glass production gives alumina which enhances hardness, durability and chemical corrosion resistance.

Feldspar as a mineral filler is more viscous, less costly and enhances adhesion property.

Fluxing Ability: High alkali content (Naâ‚‚O, Kâ‚‚O) lowers melting points in glass and ceramics.

Chemical Inertness: Ensures compatibility with other raw materials and stability in end products.

Brightness and Whiteness: Critical for ceramics, glass, and paints.

Low Iron Content: Prevents discoloration and improves product quality.

Particle Size and Shape: Fine, sub-angular particles are best for fillers and extenders.

Different Grades of Feldspar Lumps

Feldspar’s versatility stems from its varied grades and unique properties, making it a cornerstone of industries like glass, ceramics, and plastics. Selecting the right grade whether soda feldspar, potash feldspar, or a custom blend ensures optimal performance and product quality. As technology and sustainability demands evolve, understanding feldspar grades and their industrial uses remains essential for manufacturers and end-users alike.

At Mactus Minerals, we specialize in providing mineral solutions, including premium grades of feldspar, kaolin, quartz, ball clay, and talc, tailored to meet the unique needs of diverse industries. Whether you need ceramic-grade feldspar, glass-grade quartz, or micronized talc for coatings, our comprehensive product portfolio is engineered to deliver results.

The main grades are soda feldspar, potash feldspar, and blended feldspars, each defined by their alkali content, purity, and intended industrial use.

Soda feldspar’s high sodium and low iron content make it ideal for glass, while potash feldspar’s potassium content enhances vitrification and strength in ceramics.

Grade affects melting behavior, color, strength, and chemical durability in glass and ceramics, as well as brightness and performance in fillers.

Yes, regional availability and the environmental impact of mining and processing can influence grade selection and sourcing.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |