Connect With Our Team

Clay is widely used in many industries, especially in the ceramics industry, because of its special features and purpose. When it comes to types of clay, two types that are grown differently because of their difference in properties and application are ball clay and kaolin clay. In this extensive guide on wedgwood clay and ball clay, this writer will also endeavor to discuss the differences that can be found between these two types of clays with regards to their mineral composition, physical characteristics, thermal properties, and usage.

Clays are sedimentary particles that are mature rocks made of fine-grained minerals made from the breakdown of feldspar and other minerals. These are grouped according to the mineral composition, the plasticity, and the behavior when exposed to heat. Among the two classification clays that we will discuss in this paper: ball clay and kaolin clay, they come from the same parent group or family, but their properties are quite distinct.

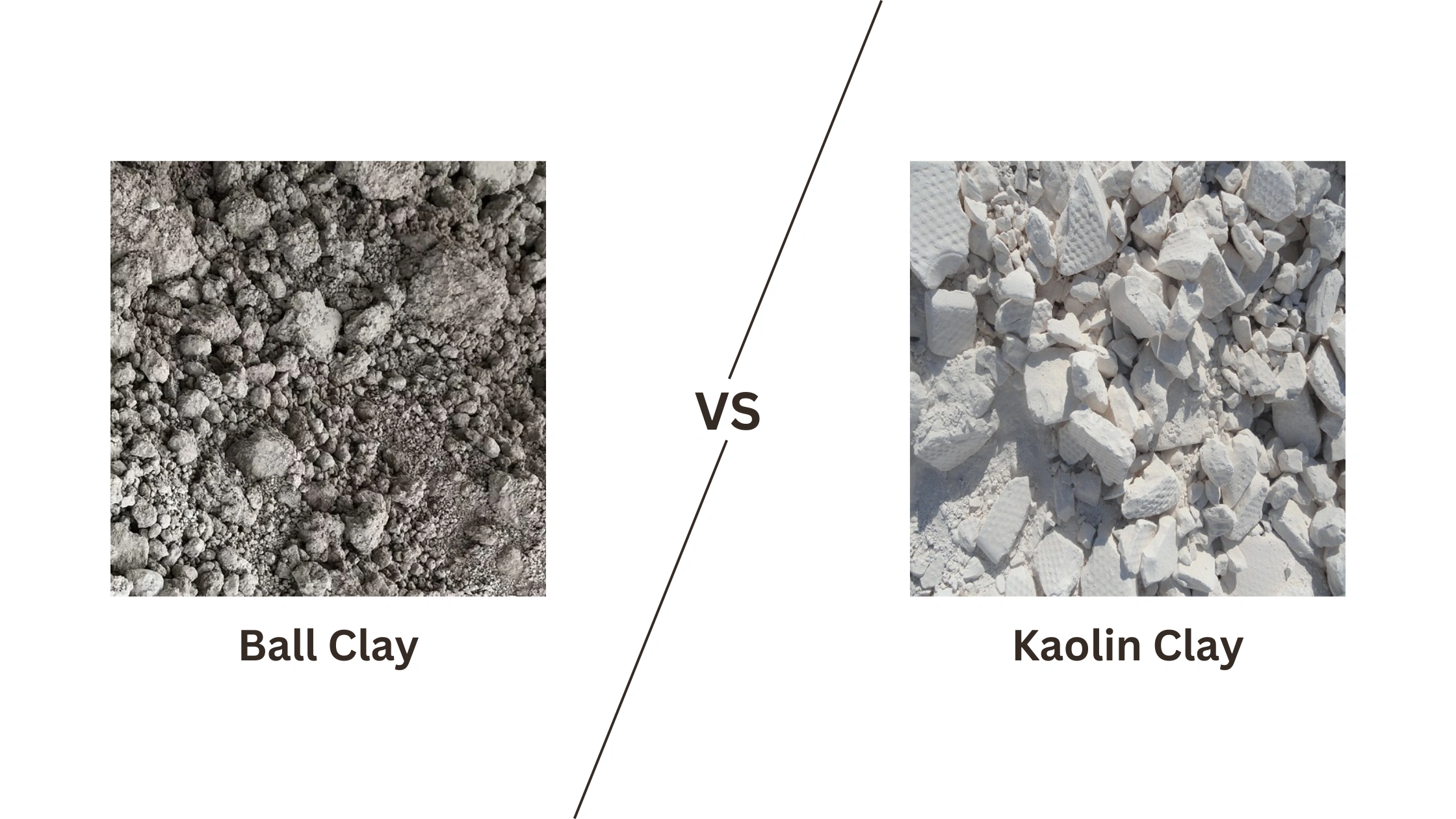

Ball Clay is a variety of clay that is perhaps the most plastic belonging to the china clay group and is mainly made up of kaolinite, mica and quartz. These include fine particle size with high organic matter that provide the smooth texture, and good molding properties.

High Plasticity: Very easy to shape, can be used for shaping tough to mold shapes.

Dark Color in Raw Form: because of the high concentration of organs in its composition.

Fine Texture: The company makes perfect shiny surfaces once fired.

This paper will focus on discussing Kaolin Clay also referred to as China Clay, and it is made up of almost 100% kaolinite. It has low proportions of organic matter and has a fine, flocculent structure which gives it this snow-white lustre when it is fired.

High Plasticity: Very much conformable; therefore suitable for complicated designs.

Dark Color in Raw Form: As a result of the high organic content.

Fine Texture: The article also gives information that it can produce smooth surface finishes if fired.

Ball Clay: Average it has more of kaolinite, mica, quartz and more organic content as compared to rest of the clay samples.

Kaolin Clay: Containing predominantly of kaolinite the extent of the impurities encountered are negligible.

Ball Clay: Is categorized by the particle size of less than 0.5 micrometers which means the grains form a denser mass and better plastic deformability. Due to the small particle size the material is easier to mold especially during the process of production.

Kaolin Clay: The dry material is coarser that the ball clay, has bigger (1-2 microns) particles and it is less plastic material.

Ball Clay: High plasticity based on particle size and mineral content of this material. Due to this property it has been widely used in molding such as throwing in a potters wheel or pressing in molds.

Kaolin Clay: Has lower plasticity due to it having more bulker particles size than finer and a higher purity. Although it can be molded, it has much less pliability than ball clay does.

Ball Clay: Usually it possesses a higher packing density in relation to its coarser and more open structure.

Kaolin Clay: Certainly it is less dense than both halite and gypsum owing to its having relatively bigger particles and a more open structure.

Ball Clay: Can be often grey or brown depending on the presence of colouring material such as organic colour or iron oxide.

Kaolin Clay: Usually white or off white since it has less contrasting defects or flaws.

Ball Clay: Burning at a lower temperature, but has a higher tendency to shrink.

Kaolin Clay: Does not deform at relatively high temperatures and therefore is suited to porcelain.

| Feature | Ball Clay | Kaolin Clay |

| Composition | High plasticity with a mix of kaolinite, quartz, and organic materials. | Primarily composed of kaolinite with minimal impurities. |

| Color (Raw) | Greyish or brown, darkens upon firing. | Naturally white, remains white when fired. |

| Color (Fired) | Ranges from off-white to darker shades. | Pure white or slightly off-white. |

| Texture | Fine-grained and smooth. | Coarser and chalky. |

| Hardness | Softer, easier to process. | Harder, more durable after firing. |

| Specific Gravity | 2.4–2.6 | 2.6–2.8 |

| Applications | Ceramics, tiles, sanitaryware, and bricks. | Paper, porcelain, cosmetics, and paint. |

Ball clay is widely used in:

Ceramics: High plasticity makes it useful in manufacturing of various types of ceramic products such as ceramic whiteware products such as dinner sets, sanitaryware mainly; toilets, tiles and figurines.

Refractories: Many manufacturers apply it in the production of refractory bricks that are used in kilns or furnaces where high temperatures are produced.

Electrical Insulators: That is why it is applied on electrical parts because of its ability to insulate.

Tableware and Pottery: Primarily for manufacture of tiles, dinner sets and decorative articles.

Sanitary Ware: Meets the required glossy surface important of bathroom fixtures.

Refractory Materials: Provides good heat resistant to bricks and industrial lining applications.

1. Ceramic Tiles: Ball clay is used as an ingredient in the formulation of tile body since it imparts the required plasticity to form the tiles and also gives the required strength to the tile body so that it will not crumple during firing.

2. Sanitaryware: It tends not to be brittle and create smooth working surfaces on such items as toilets and sinks but at the same time remain strong.

Kaolin’s purity makes it suitable for:

Porcelain Production: Criticized because it’s a prerequisite of forming excellent porcelain products without compromising on whiteness and translucency.

Paper Industry: Used as a filler and a coating material, to enhance printability and brightness of the product.

Paints and Coatings: This blends in to tackle issues within the surface and to give it a better polished surface view.

Cosmetics and Pharmaceuticals: Used widely in face masks, powders, and also in medicine.

1. Porcelain Dinnerware: This characteristic of kaolin makes it possible to produce plateaus that are not only beautiful to look at but also are also hard wearing .

2. Cosmetic Products: The reason why kaolin is good for use especially developing products for skin is because of its soft particles.

Ball clay and kaolin clay are important industrial minerals in ceramics, construction, and paper making industries however; they have different characteristics suited to specific uses. Plasticity and particle size of ball clay are suitable for carved patterns in ceramics whereas special attributes such as purity and whiteness of kaolin are compulsory for making porcelain, paper, and coatings.

Comparing these two types of clays makes it easier to know which of them is more appropriate to be used to produce a certain product since manufacturers want items that will give the best performance. At Mactus, we ensure the highest quality clays tailored to meet diverse industrial requirements.

Ball clay is primarily used in ceramics, sanitary ware, and refractory materials.

Kaolin clay acts as a filler and coating to enhance the brightness and smoothness of paper.

Yes, they are often blended to achieve the desired plasticity and finish.

Kaolin clay is preferred due to its purity and gentle properties.

Mining can disrupt ecosystems, but sustainable practices like land rehabilitation can mitigate the impact.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |