Connect With Our Team

When one considers clay, he may think of pottery or modeling compound that kids play with. On the other hand, industrial clay plays a very important role in various manufacturing processes in diversified industries. Industrial clays are a group of a few materials with special properties; operations on many fields would grind to a halt—not only with ceramics and paper, but also in oil drilling and environmental remediation. You will find in this article a whole world of industrial clays, getting to know about their unique characteristics and diversified applications. Knowing the different ways that types of clay have been used, along with their properties, will help make decisions for your industrial projects or give you greater appreciation for the materials that shape today's modern world.

Industrial clays belong to that category of versatile and vital materials used in various sectors. The fine-grained, naturally occurring minerals have various applications due to their unique properties. Understanding the characteristics and uses of industrial clays would thus be very important for any professional working in the manufacturing, construction, and environmental industries.

Industrial clays are mainly classified into four major types:

1. Kaolin(China Clay)

2. Bentonite Clay

3. Ball clay

4. Fire clay

Each type possesses different properties that make it suitable for specific industrial applications.

Industrial clays exhibit the following properties that make them commercially significant:

1. Plasticity

2. Particle size and shape

3. Surface area

4. Chemical composition

5. Thermal stability

These characteristics are what control the clays' behavior when mixed with water, heated, or subjected to different chemical processes.

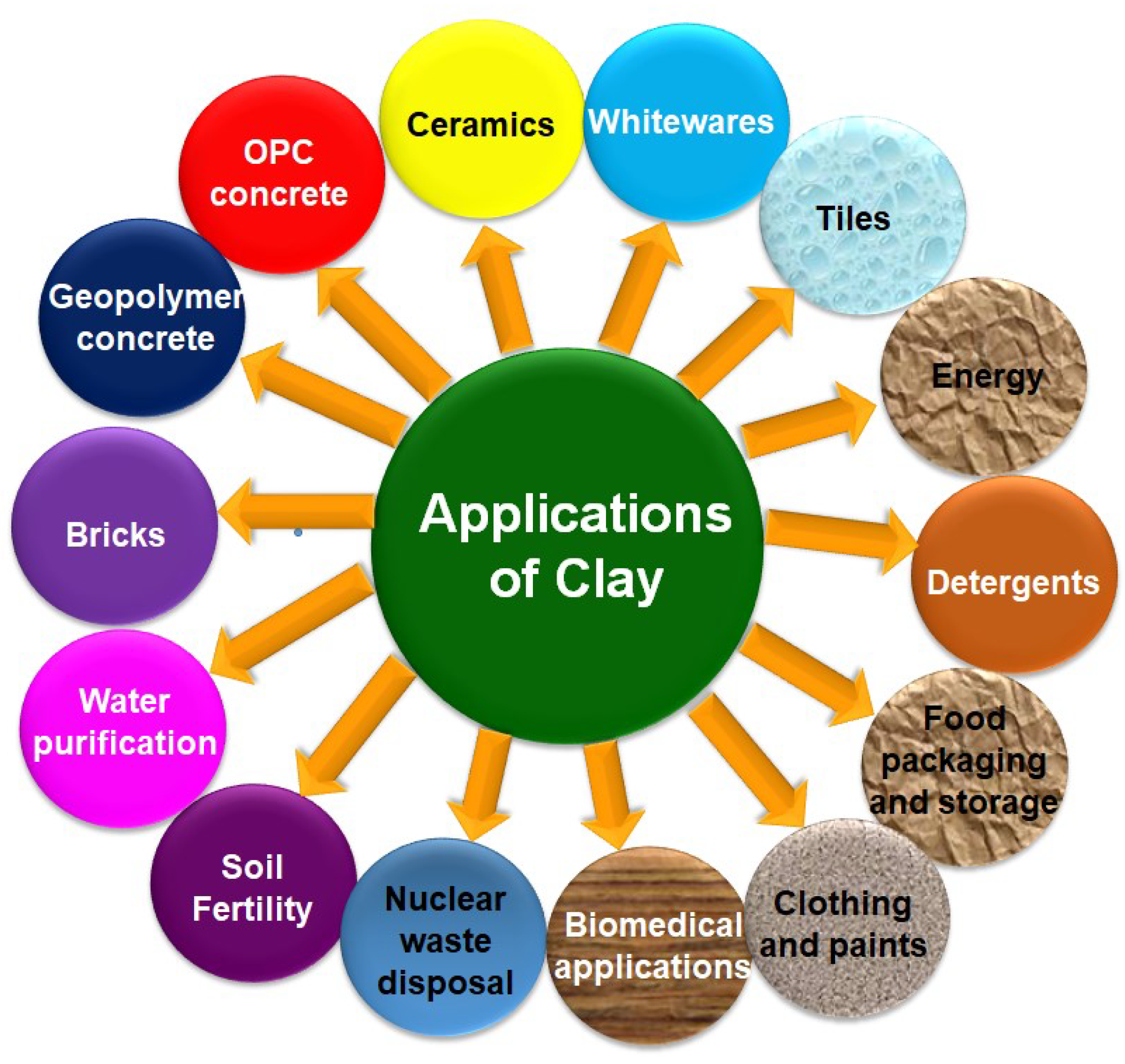

You will find industrial clays in a variety of products and processes:

1. Manufacturing ceramics and porcelain

2. Paper coating and filler

3. Refractory materials

4. Drilling muds for oil and gas exploration

5. Environmental remediation

6. Foundry molds and cores

Industrial clays, owing to their versatility, become indispensable in modern industry, contributing to the creation of objects of very wide application and specialized materials. Their use in a variety of industries is connected with understanding their properties and areas of application. It was necessary to optimize their use within the various sectors to ensure effective and efficient exploitation of such valuable natural resources.

Industrial clays are extensively used in a number of manufacturing processes. Knowing their characteristics and applications will help to use the best among these many types of clays for your needs. Here are four major types of industrial clay you need to be aware of:

Kaolin, or China clay, is an industrial clay of tremendous versatility and demand. The fine-grained, white clay consists of high purity and low iron content. You will find kaolin extensively used in:

Paper production for coating and filling

Ball clay - It is a fine-grained, highly plastic sedimentary clay. You will enjoy its excellent plasticity and high dry strength, making it ideal for the following industries/uses:

Bentonite is a clay that is formed from volcanic ash. It mainly is known for its ability to absorb water and expand. You will find bentonite used in:

Its very swelling properties and high cation exchange capacity make bentonite valuable in diversified industries.

The fire clay is a heat-resistant clay having high alumina and silica content. You will come across fire clay in uses, which involve resistance to high temperatures such as:

The ability of this fire clay to bear extreme heat in many industrial processes makes it a very useful material.

Industrial clays find application in many sectors because of their varied properties and versatility. You will find these materials utilized across a very wide range of applications, stretching from everyday consumer products to specialized industrial processes.

You will meet industrial clays as key raw materials used in coating and filling operations to improve paper quality and printability in the paper industry. In ceramics and refractories, these clays form the primary raw material for producing tiles, sanitaryware, and other high-temperature resistant wares by providing plasticity and strength.

You will notice the significance of industrial clays in construction, where they are used in cement and concrete, and also as soil stabilizers. Within paints and coatings, these clays function as performance fillers and rheology modifiers, enhancing product performance and durability.

Industrial clays also work in drilling fluids, providing viscosity and fluid loss control while exploring for oil and gas. You will also find them in iron ore pelletizing for the improvement of strength and quality of pellets in producing steel.

For instance, in agriculture, you'll find industrial clays as binders in animal feed and as carriers of nutrients in fertilizers. The cosmetics and pharmaceutical industries take advantage of these clays for their absorbency and texturizing properties in such things as facial masks and tablets.

Having looked at so many applications of this nature, it is clear that an impression of the broad effect of industrial clays can be made on a wide array of industries, underlining their necessity in modern manufacturing and consumer goods production.

As you may learn, industrial clays come in many varieties that bear peculiar properties suited for different applications. It ranges from the plasticity of ball clay to heat resistance, as in the case of fire clay— knowing these characteristics is critical in choosing the right clay for your industrial needs. Be it ceramics, construction, or environmental remediation, choosing the appropriate type of clay really makes a huge difference in the success of your project. Taking into consideration variables such as particle size, chemical composition, and thermal properties, you can make properly informed decisions to ensure your industrial processes are optimized. Improvement in technology has brought new uses for these versatile materials, which ensures that industrial clays continue being vital components in various industries for years to come.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |