Connect With Our Team

When exploring the world of industrial minerals, few are as versatile and widely used as sodium feldspar. This naturally occurring mineral affects a range of industries from ceramics to glass manufacturing, paints to plastics, even the building industry. What is exactly sodium feldspar? So why is it so vital, and how is it used by so many sectors?

This guide will not only cover the vital facts about sodium feldspar, but will also give you a comprehensive understanding of its properties, uses, processing, as well as information on other feldspars, and much more.

A type of feldspar mineral, sodium feldspar contains mainly a high percentage of sodium (Na) in the form of albite (NaAlSi₃O₈). It is in the plagioclase feldspar series, and it is found both in igneous and metamorphic rocks. Its chemical composition makes it a perfect choice for use in industries where fluxing properties are needed — particularly in the fields of ceramics and glass making.

Chemical Formula: NaAlSi₃O₈

Mohs Hardness: 6–6.5

Melting Point: ~1100°C

Density: 2.6 – 2.8 g/cm³

Cleavage: Perfect in two directions at nearly 90° angles

Color: White, grey, or pale shades

Luster: Vitreous to pearly

Crystal Structure: Triclinic

The following are the key stages of turning raw sodium feldspar into a usable product:

Mining: Sodium feldspar is almost always mined from open pit mines. It is blasted, excavated and transported to processing plants.

Feldspar Processing: The feldspar minerals are processed from the crushed, ground material.

Separation: Feldspar is separated from impurities such as quartz, mica, and iron oxides by methods of flotation, magnetic separation and screening.

After purification, the material is dried and packaged relative to the specific industrial application, frequent cases being in powder or granule form.

There are three major types of feldspars used in industry:

Sodium Feldspar (Albite)

Potassium Feldspar (Orthoclase or Microcline)

Calcium Feldspar (Anorthite)

The main difference lies in their alkali content—sodium, potassium, or calcium. Sodium feldspar is often preferred for applications that require:

Lower firing temperature (in ceramics and glass)

A smoother finish

Lower iron content for brighter colors

Potassium feldspar, on the other hand, is more commonly used in high-quality porcelain and glassware due to its slightly different fluxing properties. Calcium feldspar has more niche applications.

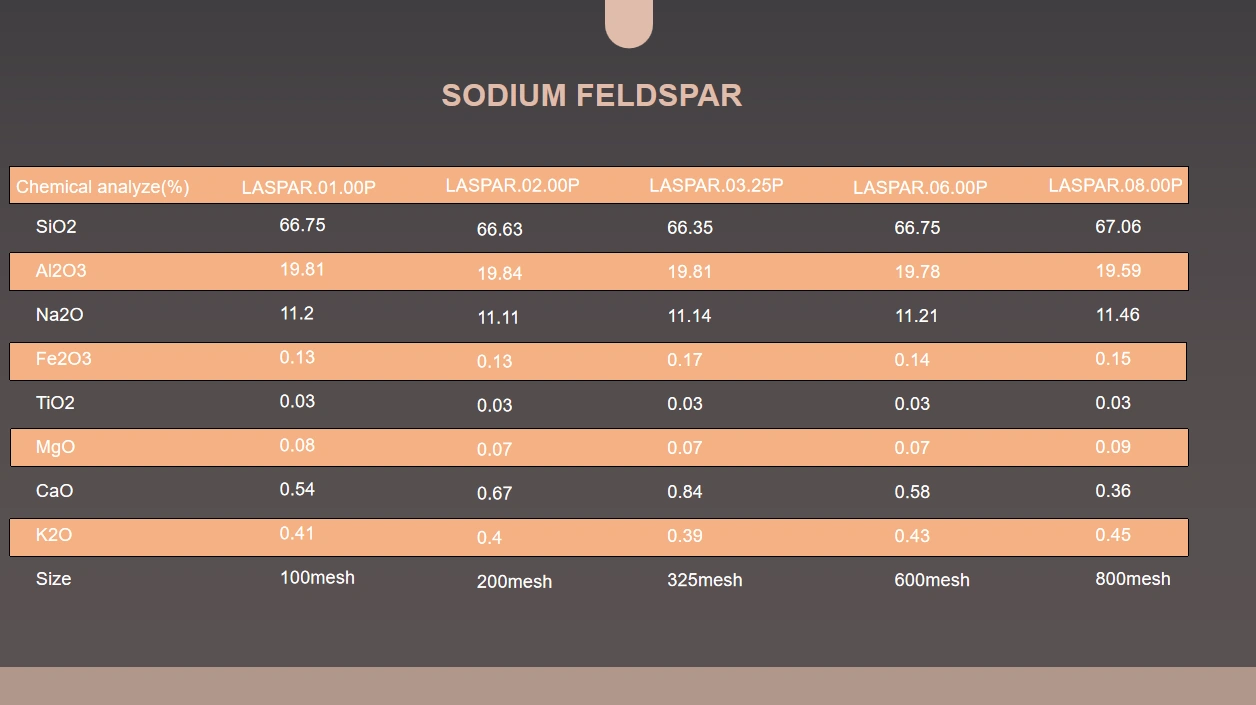

Mesh size refers to the particle size of ground sodium feldspar and is a crucial factor in determining its suitability for various applications. It is measured in terms of the number of openings per linear inch in a sieve screen.

Here’s a breakdown of common mesh sizes and their applications:

200 mesh - Fine ceramics, high-gloss glazes, paint fillers

150 mesh - Glass manufacturing, ceramic tiles, sanitary ware

100 mesh - General-purpose ceramics, flux for glass and enamel

80 mesh - Industrial abrasives, rubber, and adhesives

Selecting the right mesh size depends on your application needs:

Finer mesh (200 mesh): Ideal for coatings, fine ceramics, and glazes that require a smooth, uniform surface.

Coarser mesh (80–100 mesh): Suitable for bulk ceramics, adhesives, and where less refinement is needed.

Ceramic Industry: Sodium feldspar is a fluxing agent in ceramic bodies, glazes and enamels. It helps vitrify the process, reduces melting temperature, increases strength and gloss in final products.

Glass Manufacturing: Sodium feldspar is used in the manufacture of glass at high temperatures (it lowers the melting point of quartz and improves the transparency and durability of glassware).

Paints and Coatings: Featuring an alumina content that increases hardness and Chemical Resistance in paint formulations, sodium feldspar is a desirable extender and filler.

Plastic and Rubber: In plastics it acts as a functional filling and it increases dimensional stability, thermal resistance and mechanical strength.

Abrasives and Adhesives: The mineral’s hardness and chemical stability qualifies it for use in polishing compounds and some types of adhesives.

Cost-effective fluxing agent

Increases durability and finish of ceramic and glass products

Resists corrosion and wear in paints and coatings.

It helps to make energy efficient in high temperature processes.

The global sodium feldspar market has seen steady growth due to rising demand in construction, automotive, and consumer goods.

Growing infrastructure development in Asia-Pacific and the Middle East

Increasing demand for ceramic tiles and sanitary ware

Expanding glass and paint industries

Innovations in ceramic glaze chemistry

Increased use of feldspar in sustainable building materials

Enhanced purification methods for ultra-low iron content feldspar

According to industry estimates, the feldspar market is expected to grow at a CAGR of around 5% over the next five years.

Sodium feldspar is an indispensable mineral that drives innovation across multiple sectors. From enhancing ceramic durability to improving glass clarity and aiding metal extraction, its applications are vast and varied.

At Mactus Minerals, you’ll find high-purity Soda Feldspar tailored to a wide range of industrial needs. Our material is finely processed, available in multiple mesh sizes, and tailored to enhance your product performance—whether you're creating fine ceramic tiles, clear glassware, or industrial coatings.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |