Connect With Our Team

You're probably drinking from a glass made with feldspar right now. But do you know what this basically universal mineral is brought here from and how it gets in? This is a big and complex process, how soda feldspar goes from deep underground to nestle in your hand in sparkling glass. From a dark, dusty mine to a finished product how does a sack of basic rocks get from A to B?

From explosive methods of extraction, we're going to get into fastidious purification and quality control, so you'll understand that humans have the power to transform raw minerals into a major part of modern life. So let's dig into all the details and find out how simple rocks are shaped into a very important part of sophisticated glass and ceramics. The process is surprisingly high-tech in general and low-tech in the way it is carried out.

Finding Deposits: This involves delineating soda feldspar deposits, which the geologist does after analyzing rock samples and data from satellite imagery. Subsequently, test drilling is undertaken to know if a deposit is large enough to be commercially mined.

Open-Pit Mining: At present, so much soda feldspar is produced using open-pit mining, which means that the overburden, made up of soil and rock over the deposit, is stripped away by bulldozers and excavators. Drilling and explosion of the feldspar-bearing rock into large fragments, which are then hauled to the processing plant, follow.

Underground mining: The human-operated mines are underground, if open-pit mining is impossible. They carry out the ore, which is mined from tunnels and shafts, to the surface for further processing. This kind is more high-tech and expensive, but it offers a good ability to catch the deeply located deposits.

Transporting and storing of ores: The raw feldspar ore is transported by truck or rail to the processing facility, and stockpiled, then crushed into small pieces to facilitate further processing. Clean storage and handling prevent cross-contamination, setting the feedstock on a consistent course for high-quality soda feldspar production.

Soda feldspar is an extensive resource that can be extracted sustainably to meet the world's demand in the coming decades through ecologically sound mining practices. Mining operations from deposit location through to ore transportation must be efficiently done since this indispensable mineral is delivered to markets around the world.

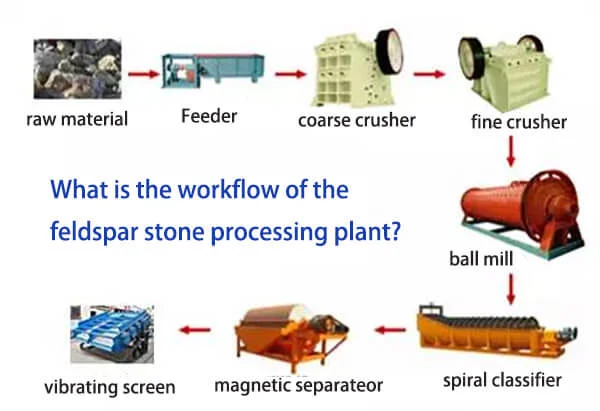

Crushing First, big lumps of soda feldspar are crushed down to small- to medium-sized rocks. The stones are then smashed by large crushers into softball-sized chunks. At the plant, processing starts by delivery of raw feldspar into the primary crusher, which breaks them into manageable-sized pieces. Usually, the process involves:

Primary Crushing: Large jaw crushers crush the raw feldspar into smaller chunks.

Secondary Crushing: Cone or impact crushers that take still smaller materials and further reduce them to the desired fineness.

Grinding: The crushed feldspar is further ground to a fine powder using ball or hammer mills. In this step, grinding serves to liberate feldspar from the gangue minerals in the rock.

The following stage is that of the separation of feldspar from other minerals and from the impurities to such a degree of purity as is sought. Different methods are used, as follows:

Magnetic separation: Mostly, this is the process through which the iron-bearing minerals are taken out of the feldspar powder by magnetic separation.

Froth flotation: Feldspar is separated from the other nonmagnetic minerals by froth flotation. Chemicals are used that cause feldspar to stick to the air bubbles and rise to the water's surface, from which it is then skimmed off.

Washing and Dewatering: The cleaned feldspar is washed of all residual impurities and dewatered with filters or centrifuges.

This is followed by purifying the feldspar through drying and sizing to meet some industrial grades:

Drying: The feldspar is subjected to drying within rotary dryers or fluid bed driers on the basis of the moisture content in the desired specification.

Screening and classification: Screening of the dried feldspar with the vibrating screens grades it into different size fractions in the interest of a uniform particle size distribution.

Highly defined quality control measures are considered throughout the manufacturing process so that the final product meets the industry standards.

Sampling and Testing: Samples can be taken at different stages or during production and tested based on the chemical nature, particle size distribution, or other quality-related characteristics.

Continuous Monitoring: Advanced monitoring systems keep track of the production process in real-time, thus making it possible to make corrective actions without delay in order to preserve the development of quality.

Last process is packaging the processed feldspar ready to be shipped and delivered to customers in all parts of the world:

Packaging: Feldspar packaging is done based on customer specific needs, either in bags or containers for bulk volume. The design of packaging ensures proper holding and containment of the product during the logistics to the storage area and in the storage area itself.

Logistics and Distribution: Proper logistic processes of feldspar ensure that feldspar is delivered within the specified line of industries on time. Apart from this, export clearance formalities are also completed according to international trade limitations.

Soda feldspar is a key ingredient in ceramic and glass production. Ceramic manufacturers use it as a flux, which helps lower the melting point of silica and alumina during firing. This allows ceramic materials to be formed at lower temperatures, saving energy and cost. Soda feldspar also adds hardness, durability, and chemical resistance to ceramic products like tiles, sanitary ware, tableware, and pottery.

The glass industry depends on soda feldspar as a flux and alumina source. Soda feldspar helps glass melt at a lower temperature and produces durable, scratch-resistant glass. It’s used to make container glass, flat glass for windows, and glass fiber for insulation. Without soda feldspar, the glass would be difficult to produce and lack important qualities.

Fine-ground soda feldspar works well as an extender or filler in paints, plastics, and rubber. It helps reduce costs and improve properties like weather resistance, hardness, and chemical stability. Soda feldspar fillers are chemically inert, non-toxic, and compatible with most polymer systems. They provide an economic way to enhance the qualities of plastics, paints, and other materials.

Soda feldspar has a wide range of important uses thanks to its unique chemical composition and physical properties. From ceramics and glass to fillers, this versatile mineral is essential for manufacturing and industry. Although new materials emerge, soda feldspar remains crucial for producing many of the products we depend on every day.

So there you have it - the step-by-step process of how those little soda feldspar granules that give your ceramic glazes their signature sheen are transformed from raw mineral to refined product. From the backbreaking labor of quarry workers to the mechanized separation and purification done in processing plants, it takes a lot of work by a lot of people to get feldspar from the ground into your hands.

The next time you open up a bag and see those sparkly grains inside, take a moment to appreciate the long journey they've been on. With an understanding of the effort involved, you can use your materials thoughtfully and recognize that even the most ordinary-looking components of your craft have an extraordinary history.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |