Connect With Our Team

As you explore the world of industrial minerals, few are as versatile and important as processed feldspar. This group of rock-forming minerals is abundant and utilized in a number of manufacturing sectors in today's world. Be it ceramics, glass, paints, or plastics, the uses of feldspar seem endless in the diverse products you get in touch with every day. In this article, you will learn how huge the role of processed feldspar is in industries and why it remains a basic fundamental material in most industries. Thereafter, understanding the importance of feldspar will further put more sense into its effect on modern manufactured goods and consumer goods.

Processed feldspar is refined from the naturally occurring mineral feldspar, which has been considered to a large extent to be one of the most common rock-forming minerals on Earth. This versatile material assumes important missions in various industrial applications thanks to the peculiar properties and composition it possesses.

Processed feldspar begins in quarries where the raw feldspar is mined from igneous rock formations. Such deposits are usually extracted through open-pit methods, whereby heavy machinery breaks the rock and gathers the mineral-rich material.

Extracted raw feldspar undergoes a series of beneficiation steps to enhance quality and purity as follows :

Crushing and grinding: The raw material is reduced to smaller, uniform particles.

Screening: Particles are classified into uniform sizes.

Flotation: Removal of unwanted minerals from the feldspar.

Magnetic Separation: Removal of any remaining magnetic impurities.

The refined feldspar will undergo final processing stages to meet the requirements of specific industries:

Drying: Moisture is removed to improve handling and storage.

Milling: The material is ground to attain desired particle sizes.

Blending: Different grades may be mixed to create custom formulations.

Through these meticulous steps, raw feldspar gets converted into a high-grade, processed product ready for use in a number of industrial applications. This is a product of improved purity, controlled size, and customized properties that turn it invaluable in many industries, such as ceramics, glass manufacture, and fillers for paints and plastics.

Processed feldspar is of importance to many industries due to its special properties. The versatile mineral will find applications in several main sectors, which use special characteristics for different uses.

In glass manufacturing, feldspar is widely used as a flux. It helps in reducing the melting temperature of the glass batch and saving energy while improving production efficiency. Besides that, feldspar contributes to the glass composition by adding alumina to increase its strength, durability, and chemical resistance.

If you analyze ceramic products, you will find the contribution or influence of feldspar to be immense. It acts as a flux in ceramic bodies and glazes, assisting in vitrification at lower temperatures. This mineral also supplies alkalis that help create a glassy phase, integral for the strength and translucency of porcelain and other high-quality ceramics.

This mineral is used as a filler and extender in paint, improving opacity, brightness, and smoothness in paint products. Other than that, feldspar also contributes to lowering the cost of production by partially replacing some rather expensive ingredients. The property of feldspar ensures paint has a consistent texture and finish; that is why they are perfectly well-suited for both interior and exterior applications.

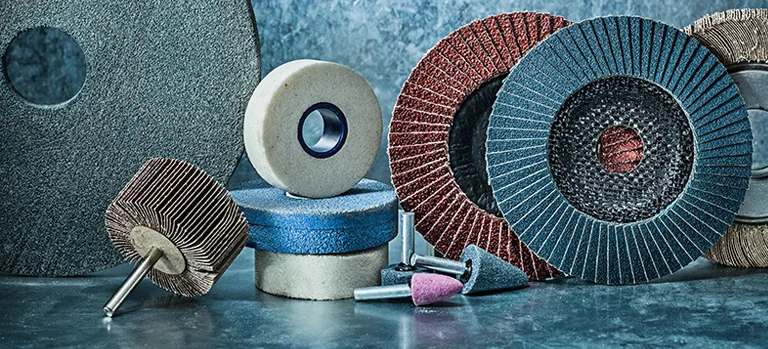

Feldspar is used for making grinding wheels, polishing compounds, etc. It finds application due to its hardness and cleavage. More than that, feldspar is used in friction materials contributing to the general performance and wear resistance.

Apart from glass and ceramic industries, you will meet processed feldspar acting as a filler in many products. In paint, it provides scratch resistance while saving on pigment costs. In plastics, feldspar increases mechanical strength and improves electrical insulation properties. You will find it in rubber compounds, improving the tensile strength and abrasion resistance of the material.

Buy High Grade Process Feldspar

Also in weld rod coatings, abrasives, and even as a mild abrasive in toothpaste, feldspar has several other uses. Its versatility secures it as a required mineral in a great number of industrial processes and consumer products you come into contact with every day.

As you have seen, processed feldspar plays a significant role across a wide range of industrial applications. From ceramics and glass to paints and plastics, this versatile mineral contributes essential properties that enhance countless products you encounter every day. Understanding the peculiarities of feldspar and its industrial uses is, therefore, very helpful in understanding manufacturing processes and material science. With advancing technology, new applications for the processed stone continue to arise, further underpinning its importance in modern industry. The appreciation of its far-reaching impact gives one respect for this abundant natural resource and its contribution toward industrial innovation, whether one works directly with feldspar or simply benefits from products containing it.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |