Connect With Our Team

Mica and talc are the most popular minerals and are used in many industries ranging from automobiles to cosmetics. Although they are but two types of material that are quite similar, they are different from each other in terms of compound, characteristic, and usage. Mica powder and talc powder are common raw materials used in products such as manufacturing of cosmetics, personal care products, among others. In this blog, you are going to learn a lot about the distinctions of mica powder from talc powder as for its features, applications, and benefits.

Mica is a mineral class of silicates that are extremely flexible in that they break into very thin layers. These sheets are very reflective and that is why mica is used in cosmetics and other commodities that need to shine on the market. Mica powder is in fact crushed and ground type of mica manufactured in the powdered form by crushing the mica mineral.

Mica powder consists of minerals including muscovite, phlogopite and biotite of which muscovite dominates the market. Mica is a complex silicate mineral which is usually associated with water and frequently with aluminum, potassium and other elements. It forms a crystalline structure, which gives it its shiny, reflective quality; this makes it ideal in as a medium for producing metal and pearl lusters.

Some of the key properties of mica powder include:

Shimmering Appearance: Mica powder is reflective in nature, which makes If added it is best for a shiny, pearlescent application.

Lightweight: Mica powder is very fine, lightweight, and does not impart any difficulty or problem when being mixed with other ingredients.

Heat Resistance: Still, heat is something that can never harm mica due to its extremely high heat tolerant property that makes it useful in products that are exposed to high heat.

Non-toxic: Mica is deemed safe for use in cosmetics: face powders and eyeshadows, for instance, contain it.

Chemical Stability: Mica is chemically inert and does not react with most of the material and hence economical for use.

Mica powder is widely used in the following industries:

1. Cosmetics: Mica powder is normally used in the manufacture of makeup products like eyeshadows, highlighters and blushes among others. It provides a gentle sheen and makes skin look better.

2. Paints and Coatings: Mica powder is applied in paints, paints and varnishes to provide the metal or pearl sheen.

3. Plastics and Rubber: In plastics and rubber products the compound mica is used as a filler to enhance the strength and give a glare.

4. Pharmaceuticals: The use of mica powder is as a filler in tablets and capsules, this because it is a non-toxic material.

5. Arts and Crafts: Mica powder is used in arts and craft especially when it is required to make an added feature to a piece of work.

Talc is the magnesium silicate mineral that has the molecule formed by magnesium, silicon and oxygen. It can be found on the Mohs scale of hardness where it is rated as the softest mineral and is common in powdered form.

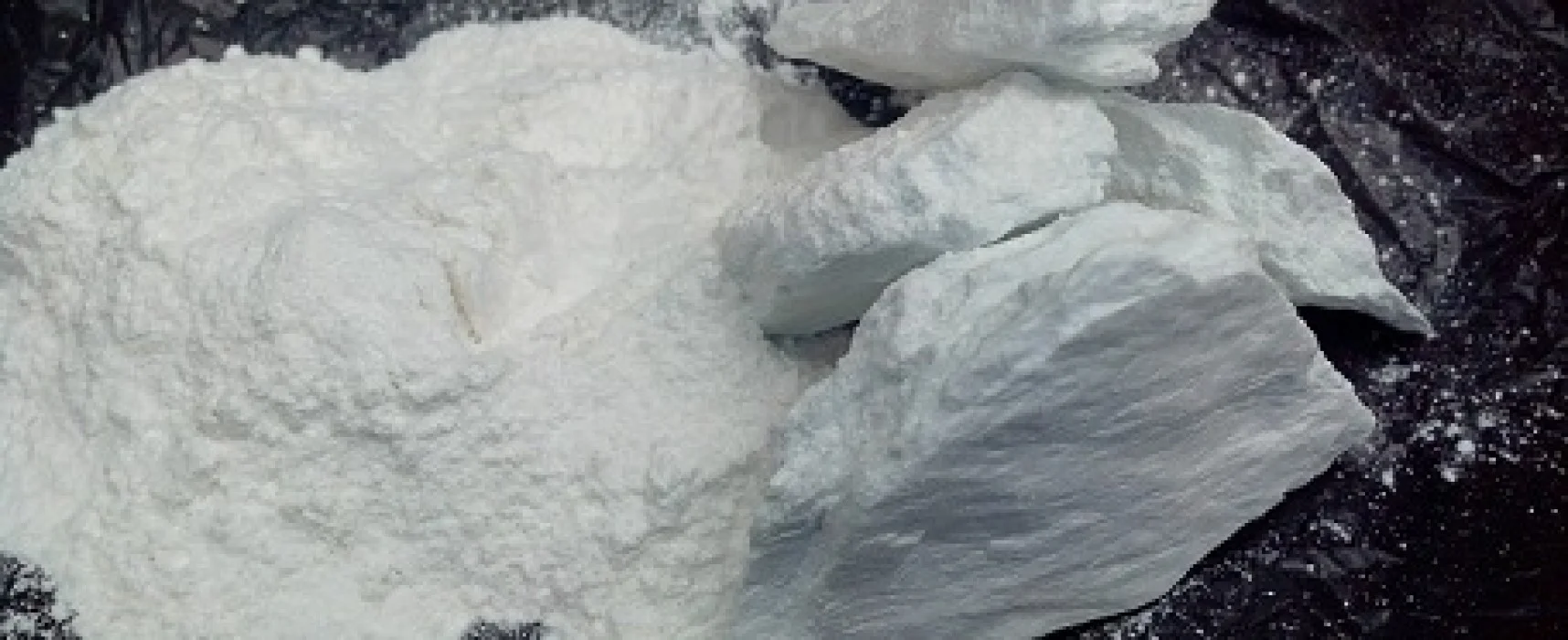

Talc powder is a fine and smooth powder which is prepared from the milling of talc. Talc on account of its softness and hydrophilic characteristics, it has been used in many ways including those which are cosmetic and those that are industrial.

Talc is made mostly of magnesium silicate and may be identified in metamorphic rocks. Potential structures range from layers that provide the petals with the ability to be crushed into a fine powder. Some key properties of talc powder include:

Softness: Talc is the softest mineral, with Mohs scale of hardness of 1.

Absorbency: Talc also has a very high absorptive capacity, that is used in wiping or absorbing of fluids.

Smooth Texture: Talc due to its particle size and consistency is easy to apply on the skin and also can be combined with other ingredients.

Non-reactive: Talc is a physiologically inactive material, which in itself has limited chemical reactivity or interaction with other chemicals.

Lubricating Properties: Talc is also used in industrial applications where it serves a purpose of providing reduction of friction between moving industrial application.

Talc powder has a wide range of applications, including:

1. Cosmetics: Talc is used in baby powder, body powders, and face powders because of its desirable physical characteristics such as a fine and slippery feel together with the ability to absorb moisture.

2. Pharmaceuticals: Talc has the ability to enhance the flow ability of ingredients during the processing of medication like tablets and capsules hence used as an excipient.

3. Paper Industry: Talc is employed in the paper industry as an additive in order to obtain better quality and to achieve improved printability.

4. Paints and Coatings: Talc powder is used in paint and coating formulations because of its ability to help control the rheology and enhance hiding power.

5. Industrial Applications: Talc is a type of clay that is employed in such applications as coefficient processes and as a constituent in plastics, ceramic, and rubber products.

| Aspect | Mica Powder | Talc Powder |

| Chemical Composition | Silicate minerals are composed of aluminum, potassium, and other elements. | Magnesium silicate, primarily composed of magnesium, silicon, and oxygen. |

| Physical Properties | Shiny, and reflective, gives a pearlescent or shimmering effect when ground. | Soft, smooth texture with excellent absorbent and lubricating properties. |

| Applications | Cosmetics (shimmering finishes), paints, plastics, rubber, arts and crafts. | Cosmetics (absorbent powders), pharmaceuticals, paper industry, industrial uses. |

| Safety Concerns | Generally considered non-toxic; avoid inhaling dust. | Potential concerns with asbestos contamination (though asbestos-free is considered safe). |

| Appearance | Shiny, reflective, available in various colors. | White or off-white with a matte finish. |

India is gifted with a huge amount of minerals and that is why it is one of the largest producers of high quality industrial minerals such as mica and talc powder. These minerals are sourced from different areas globally extraction of these minerals have been observed to be concentrated in places like Rajasthan, Jharkhand and Bihar. Mactus Mineral offers itself to businesses and manufacturers in search of high-quality mica and talc powder.

As a distributor of industrial minerals, Mactus Mineral has been hailed to offer some of the best grades of minerals in the market today, and this ranges from mica and talc powder. If you are in search of Minerals for cosmetic or manufacturing purpose or for any other industry in India then Mactus Mineral is the reliable source supplying the high quality Minerals.

Both mica powder and talc powder find extensive application in today’s world, with applications ranging from cosmetic uses to industrial applications. As mica is prized for its sparkling or shining characteristic, talc enjoys properties such as softness, absorbent characters and smooth feel. It is necessary to accentuate that choosing between these two powders, it would be appropriate to look through their peculiarities and the aimed effect that should be gained in the end product.

Thus, the systematic comparison of the properties of mica powder and talc powder will assist manufacturers, formulators, and customers to make the right decision on the application of the most suitable powder. Whether you are creating a cosmetic product or even painting a surface or creating an industrial material and many other options, you want to ensure the correct powder is chosen to get the desired result that you are after.

Whatsapp Chatx

Hi! Click one of our representatives below to chat on WhatsApp or send us email to [email protected] [email protected]

|

Mr. Vivek Rajpara +91 75750 53447 |

|

Mr. Nikunj Vadaliya +91 98240 66283 |